Page 311 - Mechanic Diesel - TT

P. 311

MECHANIC DIESEL - CITS

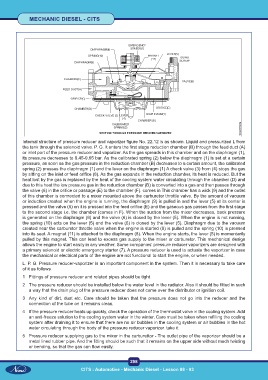

Internal structure of pressure reducer and vaporizer figure No. 22.12 is as shown. Liquid and pressurized L from

the tank through the solenoid valve. P. G. It enters the first stage reduction chamber (B) through the feed duct (A)

or inlet port of the pressure reducer and vaporizer. As the gas spreads in this chamber and on the diaphragm (1),

its pressure decreases to 0.45-0.65 bar. As the calibrated spring (2) below the diaphragm (1) is set at a certain

pressure, as soon as the gas pressure in the reduction chamber (B) decreases to a certain amount, the calibrated

spring (2) presses the diaphragm (1) and the lever on the diaphragm (1) A check valve (3) from (4) stops the gas

by sitting on the inlet or feed orifice (8). As the gas expands in the reduction chamber, its heat is reduced. But the

heat lost by the gas is replaced by the heat of the cooling system water circulating through the chamber (D) and

due to this heat the low pressure gas in the reduction chamber (B) is converted into a gas and then passes through

the valve (6) in the orifice or passage (E) to the chamber (F). comes in This chamber has a wick (9) and the outlet

of this chamber is connected to a mixer mounted above the carburetor throttle valve. By the amount of vacuum

or induction created when the engine is running, the diaphragm (9) is pulled in and the lever (5) at its center is

pressed and the valve (6) on it is pressed into the feed orifice (E) and the gaseous gas passes from the first stage

to the second stage i.e. the chamber (comes in F). When the suction from the mixer decreases, back pressure

is generated on the diaphragm (9) and the valve (6) is closed by the lever (5). When the engine is not running,

the spring (10) acts on the lever (5) and the valve (6) is closed by the lever (5). Diaphragm due to the vacuum

created near the carburetor throttle valve when the engine is started (8) is pulled and the spring (10) is pressed

into its seat. A magnet (11) is attached to the diaphragm (8). When the engine starts, the lever (5) is momentarily

pulled by this magnet. This can lead to excess gas supply to the mixer or carburetor. This mechanical design

allows the engine to start easily in any weather. Some companies’ pressure reducer vaporizers are designed with

a primary solenoid or electric emergency starter (7). A pressure reducer is used to actuate the vaporizer in case

the mechanical or electrical parts of the engine are not functional to start the engine, or when needed.

L. P. G. Pressure reducer-vaporizer is an important component in the system. Then it is necessary to take care

of it as follows.

1 Fittings of pressure reducer and related pipes should be tight.

2 The pressure reducer should be installed below the water level in the radiator. Also it should be fitted in such

a way that the drain plug of the pressure reducer does not come over the distributor or ignition coil.

3 Any kind of dirt, dust etc. Care should be taken that the pressure does not go into the reducer and the

connection of the tube on it remains clean.

4 If the pressure reducer heats up quickly, check the operation of the thermostat valve in the cooling system. Add

an anti-freeze solution to the cooling system water in the winter. Care must be taken when refilling the cooling

system after draining it to ensure that there are no air bubbles in the cooling system or air bubbles in the hot

water circulating through the body of the pressure reducer vaporizer. take it

5 Pressure reducer supplying gas to the mixer in the carburettor - The outlet pipe of the vaporizer should be a

metal lined rubber pipe. And the fitting should be such that it remains on the upper side without much twisting

or bending, so that the gas can flow easily.

298

CITS : Automotive - Mechanic Diesel - Lesson 88 - 93