Page 320 - Mechanic Diesel - TT

P. 320

MECHANIC DIESEL - CITS

7 Check Timing: Using the timing light, check and adjust the ignition timing if necessary.

8 Clean Components: Clean the distributor cap and rotor with a brush and electrical contact cleaner to remove

any dirt or rust.

9 Lubrication: Apply a small amount of dielectric grease to the inside of the distributor cap to prevent moisture

build-up.

10 Reassemble: Put the distributor cap and rotor back in place and secure them properly.

11 Reconnect the battery: Reconnect the negative terminal of the battery.

12 Start the engine: Start the engine and check for smooth running.

13 Recheck Timing: Using the timing light, recheck to make sure the ignition timing is within the specified limits.

14 Test Drive: Take the vehicle for a test drive to make sure everything is working properly.

15 Final Inspection: Once the test drive is complete, inspect the distributor and surrounding components for any

signs of leakage or deformation.

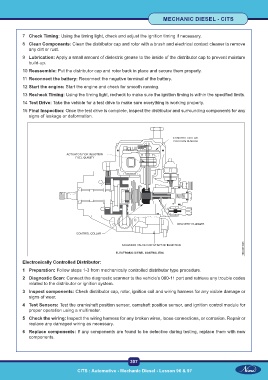

Electronically Controlled Distributor:

1 Preparation: Follow steps 1-3 from mechanically controlled distributor type procedure.

2 Diagnostic Scan: Connect the diagnostic scanner to the vehicle’s 080-11 port and retrieve any trouble codes

related to the distributor or ignition system.

3 Inspect components: Check distributor cap, rotor, ignition coil and wiring harness for any visible damage or

signs of wear.

4 Test Sensors: Test the crankshaft position sensor, camshaft position sensor, and ignition control module for

proper operation using a multimeter.

5 Check the wiring: Inspect the wiring harness for any broken wires, loose connections, or corrosion. Repair or

replace any damaged wiring as necessary.

6 Replace components: If any components are found to be defective during testing, replace them with new

components.

307

CITS : Automotive - Mechanic Diesel - Lesson 96 & 97