Page 321 - Mechanic Diesel - TT

P. 321

MECHANIC DIESEL - CITS

7 Reset the ECU: Use the diagnostic scanner to reset the engine control unit (ECU) to clear any stored trouble

codes and reset the ignition timing parameters.

8 Adjust the timing (if necessary): Using a diagnostic scanner or manufacturer-specific tools, adjust the

ignition timing to the specified value.

9 Reassemble: Put the distributor cap and rotor back in place and secure them properly.

10 Reconnect the battery: follow step 11 from the mechanically controlled distributor type procedure.

11 Start the engine: Follow steps 12-15 from the mechanically controlled distributor type procedure.

These steps should help ensure proper service of both types of distributor, keeping the vehicle’s ignition system

in good condition.

Detailed description of procedure of servicing solenoid valve controlled distributor type pumps details of start

assist systems

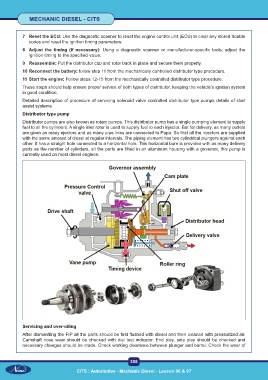

Distributor type pump

Distributor pumps are also known as rotary pumps. This distributor pump has a single pumping element to supply

fuel to all the cylinders. A single inlet rotor is used to supply fuel to each injector. But for delivery, as many outlets

are given as many ejectors and as many pipe lines are connected to Papa. So that all the injectors are supplied

with the same amount of diesel at regular intervals. The piping element has two cylindrical plungers against each

other. It has a straight hole connected to a horizontal hole. This horizontal bore is provided with as many delivery

ports as the number of cylinders, all the parts are fitted in an aluminum housing with a governor, this pump is

currently used on most diesel engines.

Servicing and over-oiling

After dismantling the FIP all the parts should be first flushed with diesel and then cleaned with pressurized air.

Camshaft nose wear should be checked with dial test indicator. End play, side play should be checked and

necessary changes should be made. Check working clearance between plunger and barrel. Check the wear of

308

CITS : Automotive - Mechanic Diesel - Lesson 96 & 97