Page 357 - Mechanic Diesel - TT

P. 357

MECHANIC DIESEL - CITS

Improved fuel economy The ability to inject fuel at any crank angle results in up to 2.7 percent better fuel economy

compared to scroll mechanical injectors. Optimum fuel economy also means reduced gaseous emissions and

less white smoke during cold engine starts.

Optimum performance The control of fuel delivered during ignition delay and main injection, known as rate shaping,

is made possible by the HEUI’s ability to operate independent of engine speed. Rate shaping modifies engine

heat release characteristics, which also helps reduce emission and noise levels. Rate shaping optimizes engine

performance by varying the idle and light load rate characteristics independent of rated and high load conditions.

Reduced smoke and particulate emissions

Since the HEUI injector’s performance does not depend on engine speed, it can maintain high injection pressures

through a wide operating range. Electronic control of these pressures helps improve emissions and low-speed

engine response.

Reduced engine noise A split injection feature leads to a more controlled fuel burn and lower noise levels.

Additional benefits include reduced shock loads as well as less wear and tear on drive train components.

Sensors, actuators and ECU (Electronic Control Unit) used

in Diesel Engines

Objectives: At the end of this lesson you shall be able to

• explain about Sensors, Actuators and ECU used in Diesel Engines.

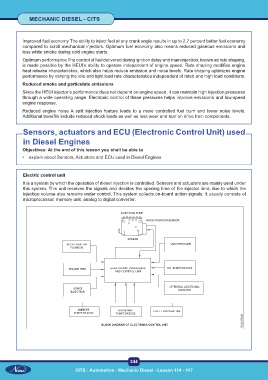

Electric control unit

It is a system by which the operation of diesel injection is controlled. Sensors and actuators are mainly used under

this system. This unit receives the signals and decides the opening time of the injector land, due to which the

injection volume also remains under control. This system collects on-board action signals. It usually consists of

microprocessor, memory unit, analog to digital converter.

344

CITS : Automotive - Mechanic Diesel - Lesson 114 - 117