Page 373 - Mechanic Diesel - TT

P. 373

MECHANIC DIESEL - CITS

When the piston turns in the right direction, then the cavity of the pump increases, as well as the liquid, can be

sucked into the cavity. These pumps are classified into three types namely plunger pumps, piston pumps, and

diaphragm pumps.

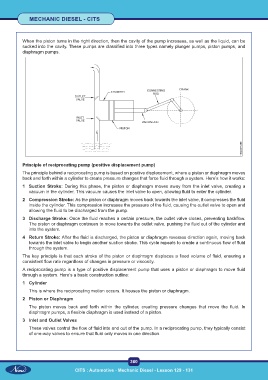

Principle of reciprocating pump (positive displacement pump)

The principle behind a reciprocating pump is based on positive displacement, where a piston or diaphragm moves

back and forth within a cylinder to create pressure changes that force fluid through a system. Here’s how it works:

1 Suction Stroke: During this phase, the piston or diaphragm moves away from the inlet valve, creating a

vacuum in the cylinder. This vacuum causes the inlet valve to open, allowing fluid to enter the cylinder.

2 Compression Stroke: As the piston or diaphragm moves back towards the inlet valve, it compresses the fluid

inside the cylinder. This compression increases the pressure of the fluid, causing the outlet valve to open and

allowing the fluid to be discharged from the pump.

3 Discharge Stroke: Once the fluid reaches a certain pressure, the outlet valve closes, preventing backflow.

The piston or diaphragm continues to move towards the outlet valve, pushing the fluid out of the cylinder and

into the system.

4 Return Stroke: After the fluid is discharged, the piston or diaphragm reverses direction again, moving back

towards the inlet valve to begin another suction stroke. This cycle repeats to create a continuous flow of fluid

through the system.

The key principle is that each stroke of the piston or diaphragm displaces a fixed volume of fluid, ensuring a

consistent flow rate regardless of changes in pressure or viscosity.

A reciprocating pump is a type of positive displacement pump that uses a piston or diaphragm to move fluid

through a system. Here’s a basic construction outline:

1 Cylinder

This is where the reciprocating motion occurs. It houses the piston or diaphragm.

2 Piston or Diaphragm

The piston moves back and forth within the cylinder, creating pressure changes that move the fluid. In

diaphragm pumps, a flexible diaphragm is used instead of a piston.

3 Inlet and Outlet Valves

These valves control the flow of fluid into and out of the pump. In a reciprocating pump, they typically consist

of one-way valves to ensure that fluid only moves in one direction.

360

CITS : Automotive - Mechanic Diesel - Lesson 129 - 131