Page 374 - Mechanic Diesel - TT

P. 374

MECHANIC DIESEL - CITS

4 Drive Mechanism

This could be an electric motor, engine, or other power source that provides the energy to move the piston or

diaphragm back and forth.

5 Seals and Gaskets

These components prevent leakage of fluid and maintain pressure within the pump.

6 Support Structure

The pump is usually mounted on a sturdy frame or base to provide stability and support during operation.

Reciprocating pumps are commonly used in various applications, including hydraulic systems, water supply, and

oil extraction.

• The plunger pumps are mainly used for pushing water.

• The piston pump is inbuilt with a piston which is used for pumping the liquid

• The diaphragm pump works similar to plunger pump however it includes diaphragm for suction & expulsion of

liquid.

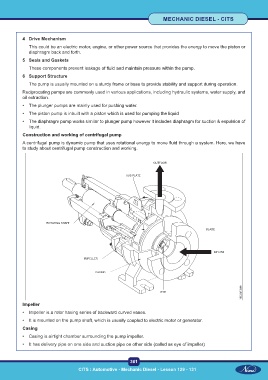

Construction and working of centrifugal pump

A centrifugal pump is dynamic pump that uses rotational energy to move fluid through a system. Here, we have

to study about centrifugal pump construction and working.

Impeller

• Impeller is a rotor having series of backward curved vanes.

• It is mounted on the pump shaft, which is usually coupled to electric motor or generator.

Casing

• Casing is airtight chamber surrounding the pump impeller.

• It has delivery pipe on one side and suction pipe on other side (called as eye of impeller)

361

CITS : Automotive - Mechanic Diesel - Lesson 129 - 131