Page 76 - Mechanic Diesel - TT

P. 76

MECHANIC DIESEL - CITS

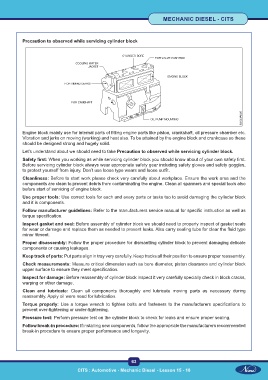

Precaution to observed while servicing cylinder block

Engine block mainly use for internal parts of fitting engine parts like piston, crankshaft, oil pressure chamber etc.

Vibration and jerks on moving (working) and heat also. To be attained by the engine block and crankcase so these

should be designed strong and hugely solid.

Let’s understand about we should need to take Precaution to observed while servicing cylinder block.

Safety first: When you working as while servicing cylinder block you should know about of your own safety first.

Before servicing cylinder block always wear appropriate safety gear including safety gloves and safety goggles,

to protect yourself from injury. Don’t use loose type wears and loose outfit.

Cleanliness: Before to start work please check very carefully about workplace. Ensure the work area and the

components are clean to prevent debris from contaminating the engine. Clean all spanners and special tools also

before start of servicing of engine block.

Use proper tools: Use correct tools for each and every parts or tasks too to avoid damaging the cylinder block

and it is components.

Follow manufacturer guidelines: Refer to the manufacturers service manual for specific instruction as well as

torque specification.

Inspect gasket and seal: Before assembly of cylinder block we should need to properly inspect of gasket seals

for wear or damage and replace them as needed to prevent leaks. Also carry sealing tube for clear the fluid type

minor fitment.

Proper disassembly: Follow the proper procedure for dismantling cylinder block to prevent damaging delicate

components or causing leakages.

Keep track of parts: Put parts align in tray very carefully. Keep tracks all their position to ensure proper reassembly.

Check measurements: Measure critical dimension such as bore diameter, piston clearance and cylinder block

upper surface to ensure they meet specification.

Inspect for damage: Before reassembly of cylinder block inspect it very carefully specially check in block cracks,

warping or other damage.

Clean and lubricate: Clean all components thoroughly and lubricate moving parts as necessary during

reassembly. Apply oil were need for lubrication.

Torque properly: Use a torque wrench to tighten bolts and fasteners to the manufacturers specifications to

prevent over-tightening or under-tightening.

Pressure test: Perform pressure test on the cylinder block to check for leaks and ensure proper sealing.

Follow break-in procedure: If installing new components, follow the appropriate the manufacturers recommended

break-in procedure to ensure proper performance and longevity.

63

CITS : Automotive - Mechanic Diesel - Lesson 15 - 18