Page 78 - Mechanic Diesel - TT

P. 78

MECHANIC DIESEL - CITS

12 Crankshaft Bore Alignment: Ensures proper alignment with crankshaft journals.

Remedy: Align honing if misaligned.

13 Main Bearing Bore Diameter: Critical for crankshaft support and alignment.

Remedy: Line boring if out of tolerance.

14 Main Bearing Bore Alignment: Ensures proper alignment with crankshaft.

Remedy: Align honing or line boring if misaligned.

15 Camshaft Bore Alignment: Critical for proper valve timing

Remedy: Align honing if misaligned.

16 Camshaft Bore Diameter: Affects camshaft support and bearing wear.

Remedy: Replace cam bearings if worn or oversized.

17 Water Jacket Integrity: Prevents coolant leaks and overheating.

Remedy: Pressure testing and repairing any leaks.

18 Oil Passages Cleanliness: Ensures proper lubrication to vital engine components.

Remedy: Thorough cleaning and flushing.

19 Head Bolt Hole Alignment: Ensures proper head bolt torque and sealing.

Remedy: Re-tapping or installing inserts if misaligned.

20 Head Bolt Hole Thread Condition: Prevents head bolt failure or stripping.

Remedy: Re-tapping or installing inserts if damaged.

21 Overall Structural Integrity: Prevents potential cracks or weaknesses.

Remedy: Inspect for cracks and repair if necessary, or replace if beyond repair.

Regular measurement and maintenance of these parameters are essential for ensuring the longevity and reliability

of the engine block.

Reasons for frequently occurring abnormal wear in cylinder block components and its effects on engine

performance

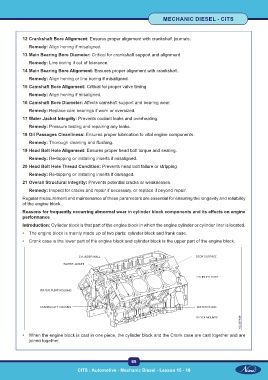

Introduction: Cylinder block is that part of the engine block in which the engine cylinder or cylinder liner is located.

• The engine block is mainly made up of two parts: cylinder block and frank case.

• Crank case is the lower part of the engine block and cylinder block is the upper part of the engine block.

• When the engine block is cast in one piece, the cylinder block and the Crank case are cast together and are

joined together.

65

CITS : Automotive - Mechanic Diesel - Lesson 15 - 18 CITS : Automotive - Mechanic Diesel - Lesson 15 - 18