Page 79 - Mechanic Diesel - TT

P. 79

MECHANIC DIESEL - CITS

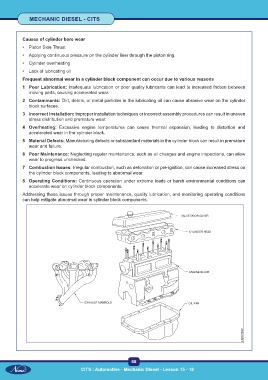

Causes of cylinder bore wear

• Piston Side Thrust

• Applying continuous pressure on the cylinder liner through the piston ring.

• Cylinder overheating

• Lack of lubricating oil

Frequent abnormal wear in a cylinder block component can occur due to various reasons

1 Poor Lubrication: Inadequate lubrication or poor quality lubricants can lead to increased friction between

moving parts, causing accelerated wear.

2 Contaminants: Dirt, debris, or metal particles in the lubricating oil can cause abrasive wear on the cylinder

block surfaces.

3 Incorrect Installation: Improper installation techniques or incorrect assembly procedures can result in uneven

stress distribution and premature wear.

4 Overheating: Excessive engine temperatures can cause thermal expansion, leading to distortion and

accelerated wear in the cylinder block.

5 Material Defects: Manufacturing defects or substandard materials in the cylinder block can result in premature

wear and failure.

6 Poor Maintenance: Neglecting regular maintenance, such as oil changes and engine inspections, can allow

wear to progress unchecked.

7 Combustion Issues: Irregular combustion, such as detonation or pre-ignition, can cause increased stress on

the cylinder block components, leading to abnormal wear.

8 Operating Conditions: Continuous operation under extreme loads or harsh environmental conditions can

accelerate wear on cylinder block components.

Addressing these issues through proper maintenance, quality lubrication, and monitoring operating conditions

can help mitigate abnormal wear in cylinder block components.

66

CITS : Automotive - Mechanic Diesel - Lesson 15 - 18