Page 52 - CITS - WCS - Mechanical

P. 52

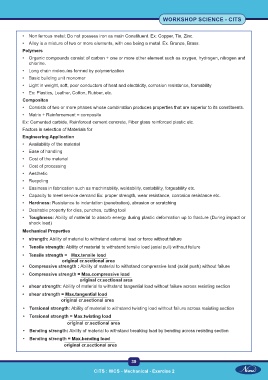

WORKSHOP SCIENCE - CITS

• Non ferrous metal: Do not possess iron as main Constituent. Ex: Copper, Tin, Zinc.

• Alloy is a mixture of two or more elements, with one being a metal. Ex. Bronze, Brass.

Polymers

• Organic compounds consist of carbon + one or more other element such as oxygen, hydrogen, nitrogen and

chlorine.

• Long chain molecules formed by polymerization

• Basic building unit monomer

• Light in weight, soft, poor conductors of heat and electricity, corrosion resistance, formability

• Ex: Plastics, Leather, Cotton, Rubber, etc.

Composites

• Consists of two or more phases whose combination produces properties that are superior to its constituents.

• Matrix + Reinforcement = composite

Ex: Cemented carbide, Reinforced cement concrete, Fiber glass reinforced plastic etc.

Factors in selection of Materials for

Engineering Application

• Availability of the material

• Ease of handling

• Cost of the material

• Cost of processing

• Aesthetic

• Recycling

• Easiness in fabrication such as machinability, weldability, castability, forgeability etc.

• Capacity to meet service demand Ex: proper strength, wear resistance, corrosion resistance etc.

• Hardness: Resistance to indentation (penetration), abrasion or scratching

• Desirable property for dies, punches, cutting tool

• Toughness: Ability of material to absorb energy during plastic deformation up to fracture (During impact or

shock load)

Mechanical Properties

• strength: Ability of material to withstand external load or force without failure

• Tensile strength: Ability of material to withstand tensile load (axial pull) without failure

• Tensile strength = Max.tensile load

original cr.sectional area

• Compressive strength : Ability of material to withstand compressive load (axial push) without failure

• Compressive strength = Max.compressive load

original cr.sectional area

• shear strength: Ability of material to withstand tangential load without failure across resisting section

• shear strength = Max.tangential load

original cr.sectional area

• Torsional strength: Ability of material to withstand twisting load without failure across resisting section

• Torsional strength = Max.twisting load

original cr.sectional area

• Bending strength: Ability of material to withstand breaking load by bending across resisting section

• Bending strength = Max.bending load

original cr.sectional area

39

CITS : WCS - Mechanical - Exercise 2