Page 113 - CITS - Welder - Trade Practical

P. 113

WELDER - CITS

• Fix nozzle No. 5 on the blow pipe and adjust gas pressure of 0.15 kg/sq.cm2 for both gases.

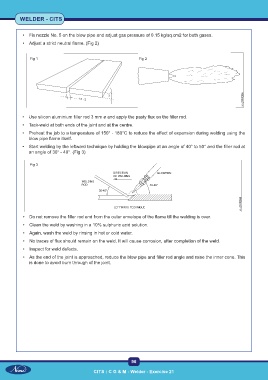

• Adjust a strict neutral flame. (Fig 2)

Fig 1 Fig 2

• Use silicon aluminium filler rod 3 mm ø and apply the pasty flux on the filler rod.

• Tack-weld at both ends of the joint and at the centre.

• Preheat the job to a temperature of 150° - 180°C to reduce the effect of expansion during welding using the

blow pipe flame itself.

• Start welding by the leftward technique by holding the blowpipe at an angle of 40° to 50° and the filler rod at

an angle of 30° - 40°. (Fig 3)

Fig 3

• Do not remove the filler rod end from the outer envelope of the flame till the welding is over.

• Clean the weld by washing in a 10% sulphuric acid solution.

• Again, wash the weld by rinsing in hot or cold water.

• No traces of flux should remain on the weld. It will cause corrosion, after completion of the weld.

• Inspect for weld defects.

• As the end of the joint is approached, reduce the blow pipe and filler rod angle and raise the inner cone. This

is done to avoid burn through of the joint.

96

CITS : C G & M - Welder - Exercise 21