Page 112 - CITS - Welder - Trade Practical

P. 112

WELDER - CITS

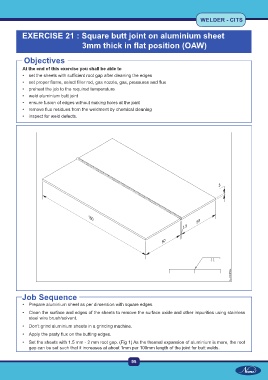

EXERCISE 21 : Square butt joint on aluminium sheet

3mm thick in flat position (OAW)

Objectives

At the end of this exercise you shall be able to

• set the sheets with sufficient root gap after cleaning the edges

• set proper flame, select filler rod, gas nozzle, gas, pressures and flux

• preheat the job to the required temperature

• weld aluminium butt joint

• ensure fusion of edges without making holes at the joint

• remove flux residues from the weldment by chemical cleaning

• inspect for weld defects.

Job Sequence

• Prepare aluminium sheet as per dimension with square edges.

• Clean the surface and edges of the sheets to remove the surface oxide and other impurities using stainless

steel wire brush/solvent.

• Don’t grind aluminium sheets in a grinding machine.

• Apply the pasty flux on the butting edges.

• Set the sheets with 1.5 mm - 2 mm root gap. (Fig 1) As the thermal expansion of aluminium is more, the root

gap can be set such that it increases at about 1mm per 100mm length of the joint for butt welds.

95