Page 107 - CITS - Welder - Trade Practical

P. 107

WELDER - CITS

Job Sequence

• Prepare the material as per drawing and file the edges to square. Clean the surface with a wire brush.

• Select nozzle No. 5 and a 1.5mmø C.C.M.S. rod. Set the neutral flame.

• Set gas pressure at 0.15 kg/cm2.

• Wear protective leather clothing and welding goggles.

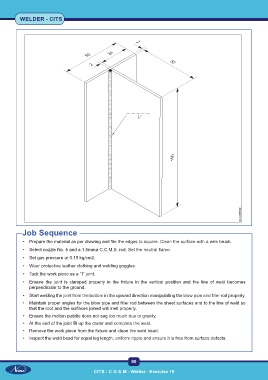

• Tack the work piece as a ‘T’ joint.

• Ensure the joint is clamped properly in the fixture in the vertical position and the line of weld becomes

perpendicular to the ground.

• Start welding the joint from the bottom in the upward direction manipulating the blow pipe and filler rod properly.

• Maintain proper angles for the blow pipe and filler rod between the sheet surfaces and to the line of weld so

that the root and the surfaces joined will melt properly.

• Ensure the molten puddle does not sag too much due to gravity.

• At the end of the joint fill up the crater and complete the weld.

• Remove the work piece from the fixture and clean the weld bead.

• Inspect the weld bead for equal leg length, uniform ripple and ensure it is free from surface defects.

90

CITS : C G & M - Welder - Exercise 19