Page 103 - CITS - Welder - Trade Practical

P. 103

WELDER - CITS

Job Sequence

• Shear the plate and file the edges. Clean the surface with a wire brush. Set the plate as a square butt with a

1.5 mm root gap.

• Fix nozzle No. 5 and adjust the gas pressure of oxygen and acetylene at 0.15 kg/cm2.

• Ignite the torch and set the neutral flame.

• Select a C.C.M.S. filler rod of 3 mm ø.

• Tack-weld the two pieces with a 1.5 mm uniform root gap on both ends and in centre.

• Check for correct alignment.

• Fix the sheet in vertical in the ‘C’ clamp with the bottom edge of the sheet at welder’s chest height.

• Melt the tack weld and establish a weld pool at the bottom edge of the joint.

• Keep the blowpipe angle 75° - 80° to the line of travel and the filler rod angle 30° to 40° to the same plane and

proceed to weld upwards.

• Continuously dip the filler rod tip in the molten pool and move upwards. Weld the joint with a single run.

• Ensure the edges of both the metals melt equally so as to achieve complete penetration.

• At the end of the joint add sufficient filler metal and fill up the crater. Use a pair of tongs to remove the job from

the fixture.

• Clean the weld and inspect for surface defects and root penetration.

Skill Sequence

Square butt joint on MS sheet 2mm in vertical position

Objectives: At the end of this exercise you shall be able to

• prepare and weld square butt joint on MS sheet 2mm in vertical position.

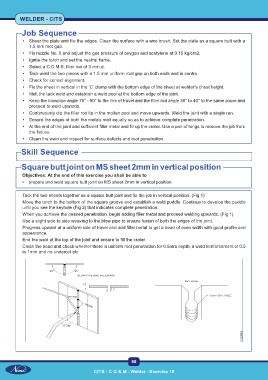

Tack the two sheets together as a square butt joint and fix the job in vertical position. (Fig 1)

Move the torch to the bottom of the square groove and establish a weld puddle. Continue to develop the puddle

until you see the keyhole (Fig 2) that indicates complete penetration.

When you achieve the desired penetration, begin adding filler metal and proceed welding upwards. (Fig 1)

Use a slight side to side weaving to the blow pipe to ensure fusion of both the edges of the joint.

Progress upward at a uniform rate of travel and add filler metal to get a bead of even width with good profile and

appearance.

End the weld at the top of the joint and ensure to fill the crater.

Clean the bead and check whether there is uniform root penetration for 0.5mm depth, a weld reinforcement of 0.5

to 1mm and no undercut etc

86

CITS : C G & M - Welder - Exercise 18