Page 105 - CITS - Welder - Trade Practical

P. 105

WELDER - CITS

Job Sequence

1 Cut the sheet by shearing machine as per drawing.

2 Grind and file the edges of sheets to square.

3 Deburr and clean the surface of the plates by carbon steel wire brush and filling.

4 Set the plate A on the plate B in the form of lap as per drawing.

5 Wear protective clothes.

6 Connect the torch to the positive terminal of the machine.

7 Set 90-100A current/corresponding wire feed rate, 19 to 20 arc voltage and deposit the run using Dip transfer

mode.

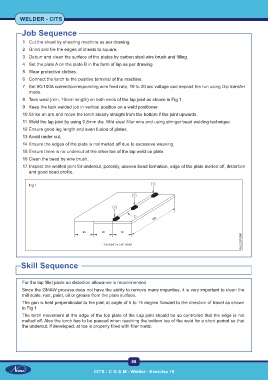

8 Tack weld (min. 10mm length) on both ends of the lap joint as shown in Fig 1.

9 Keep the tack welded job in vertical position on a weld positioner.

10 Strike an are and move the torch steady straight from the bottom if the joint upwards.

11 Weld the lap joint by using 0.8mm dia. Mild steel filler wire and using stringer bead welding technique.

12 Ensure good leg length and even fusion of plates.

13 Avoid under cut.

14 Ensure the edges of the plate is not melted off due to excessive weaving.

15 Ensure there is no undercut at the other toe of the lap weld on plate.

16 Clean the bead by wire brush.

17 Inspect the welded joint for undercut, porosity, uneven bead formation, edge of the plate melted off, distortion

and good bead profile.

Fig 1

Skill Sequence

For the lap fillet joints no distortion allowance is recommended

Since the GMAW process does not have the ability to remove many impurities, it is very important to clean the

mill scale, rust, paint, oil or grease from the plate surface.

The gun is held perpendicular to the joint at angle of 5 to 15 degree forward to the direction of travel as shown

in Fig 1

The torch movement at the edge of the top plate of the Lap joint should be so controlled that the edge is not

melted off. Also the torch has to be paused when reaching the bottom toe of the weld for a short period so that

the undercut, if developed, at toe is properly filled with filler metal.

88

CITS : C G & M - Welder - Exercise 19