Page 119 - CITS - Welder - Trade Practical

P. 119

WELDER - CITS

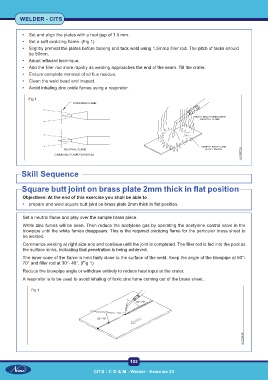

• Set and align the plates with a root gap of 1.5 mm.

• Set a soft oxidizing flame. (Fig 1)

• Slightly preheat the plates before tacking and tack weld using 1.5mmø filler rod. The pitch of tacks should

be 50mm.

• Adopt leftward technique.

• Add the filler rod more rapidly as welding approaches the end of the seam. Fill the crater.

• Ensure complete removal of all flux residue.

• Clean the weld bead and inspect.

• Avoid inhaling zinc oxide fumes using a respirator.

Fig 1

Skill Sequence

Square butt joint on brass plate 2mm thick in flat position

Objectives: At the end of this exercise you shall be able to

• prepare and weld square butt joint on brass plate 2mm thick in flat position.

Set a neutral flame and play over the sample brass piece.

White zinc fumes will be seen. Then reduce the acetylene gas by operating the acetylene control valve in the

blowpipe until the white fumes disappears. This is the required oxidizing flame for the particular brass sheet to

be welded.

Commence welding at right side end and continue until the joint is completed. The filler rod is fed into the pool as

the surface sinks, indicating that penetration is being achieved.

The inner cone of the flame is held fairly close to the surface of the weld. Keep the angle of the blowpipe at 60°-

70° and filler rod at 30°- 40°. (Fig 1)

Reduce the blowpipe angle or withdraw entirely to reduce heat input at the crater.

A respirator is to be used to avoid inhaling of toxic zinc fume coming out of the brass sheet.

Fig 1

102

CITS : C G & M - Welder - Exercise 23