Page 122 - CITS - Welder - Trade Practical

P. 122

WELDER - CITS

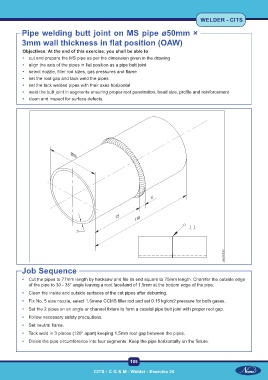

Pipe welding butt joint on MS pipe ø50mm ×

3mm wall thickness in flat position (OAW)

Objectives: At the end of this exercise, you shall be able to

• cut and prepare the MS pipe as per the dimension given in the drawing

• align the axis of the pipes in flat position as a pipe butt joint

• select nozzle, filler rod sizes, gas pressures and flame

• set the root gap and tack weld the pipes

• set the tack welded pipes with their axes horizontal

• weld the butt joint in segments ensuring proper root penetration, bead size, profile and reinforcement

• clean and inspect for surface defects.

Job Sequence

• Cut the pipes to 77mm length by hacksaw and file its end square to 75mm length. Chamfer the outside edge

of the pipe to 30 - 35° angle leaving a root face/land of 1.5mm at the bottom edge of the pipe.

• Clean the inside and outside surfaces of the cut pipes after deburring.

• Fix No. 5 size nozzle, select 1.6mmø CCMS filler rod and set 0.15 kg/cm2 pressure for both gases.

• Set the 2 pipes on an angle or channel fixture to form a coaxial pipe butt joint with proper root gap.

• Follow necessary safety precautions.

• Set neutral flame.

• Tack weld in 3 places (120° apart) keeping 1.5mm root gap between the pipes.

• Divide the pipe circumference into four segments. Keep the pipe horizontally on the fixture.

105

CITS : C G & M - Welder - Exercise 24