Page 124 - CITS - Welder - Trade Practical

P. 124

WELDER - CITS

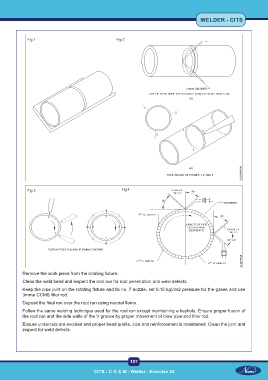

Fig 1 Fig 2

Fig 1

Fig 3 Fig 4

Remove the work piece from the rotating fixture.

Clean the weld bead and inspect the root run for root penetration and weld defects.

Keep the pipe joint on the rotating fixture and fix no. 7 nozzle, set 0.15 kg/cm2 pressure for the gases and use

3mmø CCMS filler rod.

Deposit the final run over the root run using neutral flame.

Follow the same welding technique used for the root run except maintaining a keyhole. Ensure proper fusion of

the root run and the side walls of the V groove by proper movement of blow pipe and filler rod.

Ensure undercuts are avoided and proper bead profile, size and reinforcement is maintained. Clean the joint and

inspect for weld defects.

107

CITS : C G & M - Welder - Exercise 24