Page 128 - CITS - Welder - Trade Practical

P. 128

WELDER - CITS

Job Sequence

• Ensure the correct size of pipes are used.

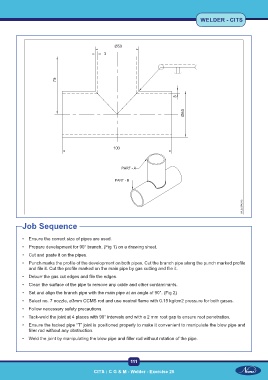

• Prepare development for 90° branch. (Fig 1) on a drawing sheet.

• Cut and paste it on the pipes.

• Punch marks the profile of the development on both pipes. Cut the branch pipe along the punch marked profile

and file it. Cut the profile marked on the main pipe by gas cutting and file it.

• Deburr the gas cut edges and file the edges.

• Clean the surface of the pipe to remove any oxide and other contaminants.

• Set and align the branch pipe with the main pipe at an angle of 90°. (Fig 2)

• Select no. 7 nozzle, ø3mm CCMS rod and use neutral flame with 0.15 kg/cm2 pressure for both gases.

• Follow necessary safety precautions.

• Tack-weld the joint at 4 places with 90° intervals and with a 2 mm root gap to ensure root penetration.

• Ensure the tacked pipe “T” joint is positioned properly to make it convenient to manipulate the blow pipe and

filler rod without any obstruction.

• Weld the joint by manipulating the blow pipe and filler rod without rotation of the pipe.

111

CITS : C G & M - Welder - Exercise 25