Page 196 - CITS - Welder - Trade Practical

P. 196

WELDER - CITS

Note: Ensure an electrode angle of 45° with the fillet corner and 80° with the welding line.

- Check the all connections before welding

- Welding area should be dry area

- Use welding screen and chipping goggle for eyes and face safety

Note: Prevent the upper edge of the plate from melting off.

• Remove the slag from the final weld and clean thoroughly.

Note: Use a weld gauge to check the fillet size.

• Inspect the lap fillet weld for surface defects and size.

Skill Sequence

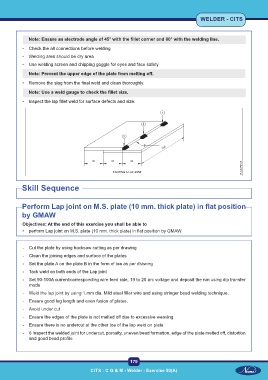

Perform Lap joint on M.S. plate (10 mm. thick plate) in flat position

by GMAW

Objectives: At the end of this exercise you shall be able to

• perform Lap joint on M.S. plate (10 mm. thick plate) in flat position by GMAW.

- Cut the plate by using hacksaw cutting as per drawing

- Clean the joining edges and surface of the plates

- Set the plate A on the plate B in the form of tee as per drawing

- Tack weld on both ends of the Lap joint

- Set 90-100A current/corresponding wire feed rate, 19 to 20 arc voltage and deposit the run using dip transfer

mode

- Weld the lap joint by using 1.mm dia. Mild steel filler wire and using stringer bead welding technique.

- Ensure good leg length and even fusion of plates.

- Avoid under cut

- Ensure the edges of the plate is not melted off due to excessive weaving

- Ensure there is no undercut at the other toe of the lap weld on plate

- 6 Inspect the welded joint for undercut, porosity, uneven bead formation, edge of the plate melted off, distortion

and good bead profile

179

CITS : C G & M - Welder - Exercise 50(A)