Page 199 - CITS - Welder - Trade Practical

P. 199

WELDER - CITS

Job Sequence

- Cut the plates by gas/hacksaw cutting as per drawing

- Set the pieces in the form of Tee as per drawing

- Tack weld on both ends of the tee joint

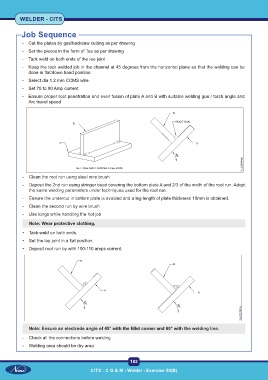

- Keep the tack welded job in the channel at 45 degrees from the horizontal plane so that the welding can be

done in flat/down hand position

- Select dia 1.2 mm CCMS wire.

- Set 70 to 90 Amp current

- Ensure proper root penetration and even fusion of plate A and B with suitable welding gun / torch angle and

Arc travel speed

- Clean the root run using steel wire brush

- Deposit the 2nd run using stringer bead covering the bottom plate A and 2/3 of the width of the root run. Adopt

the same welding parameters under techniques used for the root run.

- Ensure the undercut in bottom plate is avoided and a leg length of plate thickness 10mm is obtained.

- Clean the second run by wire brush

- Use tongs while handling the hot job

Note: Wear protective clothing.

• Tack-weld on both ends.

• Set the lap joint in a flat position.

• Deposit root run by with 100-110 amps current.

Note: Ensure an electrode angle of 45° with the fillet corner and 80° with the welding line.

- Check all the connections before welding

- Welding area should be dry area

182

CITS : C G & M - Welder - Exercise 50(B)