Page 213 - CITS - Welder - Trade Practical

P. 213

WELDER - CITS

- Clean the root run using steel wire brush.

- Ensure the undercut in bottom plate is avoided and a leg length of plate thickness 3mm is obtained.

- Clean the second run by wire brush.

- Use tongs while handling the hot job.

Note: Wear protective clothing.

• Tack-weld on both ends.

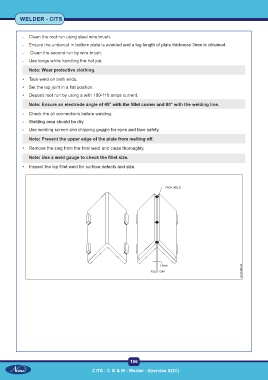

• Set the lap joint in a flat position.

• Deposit root run by using a with 100-110 amps current.

Note: Ensure an electrode angle of 45° with the fillet corner and 80° with the welding line.

- Check the all connections before welding.

- Welding area should be dry.

- Use welding screen and chipping goggle for eyes and face safety.

Note: Prevent the upper edge of the plate from melting off.

• Remove the slag from the final weld and clean thoroughly.

Note: Use a weld gauge to check the fillet size.

• Inspect the lap fillet weld for surface defects and size.

196

CITS : C G & M - Welder - Exercise 52(C)