Page 210 - CITS - Welder - Trade Practical

P. 210

WELDER - CITS

Tack weld the two plates at the ends.

Set the welding conditions: Adjust the gas flow rate to 8 to 10 LPM.

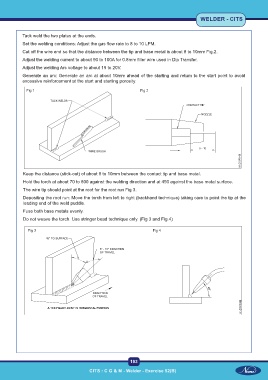

Cut off the wire end so that the distance between the tip and base metal is about 8 to 10mm Fig.2.

Adjust the welding current to about 90 to 100A for 0.8mm filler wire used in Dip Transfer.

Adjust the welding Arc voltage to about 19 to 20V.

Generate an arc: Generate an arc at about 10mm ahead of the starting and return to the start point to avoid

excessive reinforcement at the start and starting porosity.

Fig 1 Fig 2

Keep the distance (stick-out) of about 8 to 10mm between the contact tip and base metal.

Hold the torch at about 70 to 800 against the welding direction and at 450 against the base metal surface.

The wire tip should point at the root for the root run Fig 3.

Depositing the root run: Move the torch from left to right (backhand technique) taking care to point the tip at the

leading end of the weld puddle.

Fuse both base metals evenly.

Do not weave the torch. Use stringer bead technique only. (Fig 3 and Fig.4)

Fig 3 Fig 4

193

CITS : C G & M - Welder - Exercise 52(B) CITS : C G & M - Welder - Exercise 52(B)