Page 211 - CITS - Welder - Trade Practical

P. 211

WELDER - CITS

Fill the crater: Repeat it until the level of the crater becomes the same as the bead reinforcement.

Clean the scales and other non-metallic materials and spatters from the root run and the joint.

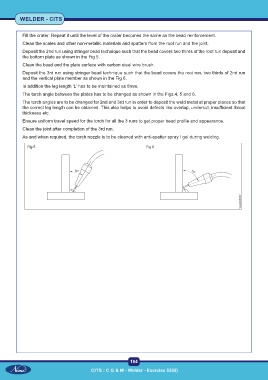

Deposit the 2nd run using stringer bead technique such that the bead covers two thirds of the root run deposit and

the bottom plate as shown in the Fig 5.

Clean the bead and the plate surface with carbon steel wire brush.

Deposit the 3rd run using stringer bead technique such that the bead covers the root run, two thirds of 2nd run

and the vertical plate member as shown in the Fig 6.

In addition the leg length ‘L’ has to be maintained as 8mm.

The torch angle between the plates has to be changed as shown in the Figs.4, 5 and 6.

The torch angles are to be changed for 2nd and 3rd run in order to deposit the weld metal at proper places so that

the correct leg length can be obtained. This also helps to avoid defects like overlap, undercut, insufficient throat

thickness etc.

Ensure uniform travel speed for the torch for all the 3 runs to get proper bead profile and appearance.

Clean the joint after completion of the 3rd run.

As and when required, the torch nozzle is to be cleaned with anti-spatter spray / gel during welding.

Fig 5 Fig 6

194

CITS : C G & M - Welder - Exercise 52(B)