Page 249 - CITS - Welder - Trade Practical

P. 249

WELDER - CITS

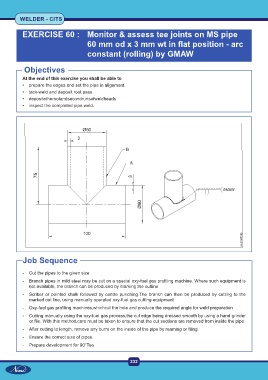

EXERCISE 60 : Monitor & assess tee joints on MS pipe

60 mm od x 3 mm wt in flat position - arc

constant (rolling) by GMAW

Objectives

At the end of this exercise you shall be able to

• prepare the edges and set the pipe in alignment

• tack-weld and deposit root pass

• depositetherootandsecondrunsofweldbeads

• inspect the completed pipe weld.

Job Sequence

- Cut the pipes to the given size

- Branch pipes in mild steel may be cut on a special oxy-fuel gas profiling machine. Where such equipment is

not available, the branch can be produced by marking the outline

- Scriber or pointed chalk followed by centre punching.The branch can then be produced by cutting to the

marked out line, using manually operated oxy-fuel gas cutting equipment

- Oxy-fuel gas profiling machines,whichcut the hole and produce the required angle for weld preparation

- Cutting manually using the oxy-fuel gas process,the cut edge being dressed smooth by using a hand grinder

or file. With this method,care must be taken to ensure that the cut sections are removed from inside the pipe

- After cutting to length, remove any burrs on the inside of the pipe by reaming or filing.

- Ensure the correct size of pipes.

- Prepare development for 90°Tee

232