Page 250 - CITS - Welder - Trade Practical

P. 250

WELDER - CITS

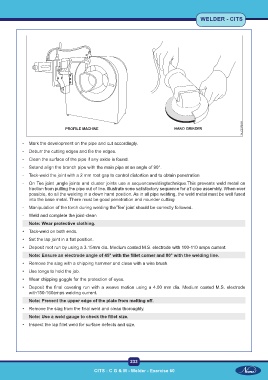

- Mark the development on the pipe and cut accordingly.

- Deburr the cutting edges and file the edges.

- Clean the surface of the pipe if any oxide is found.

- Setand align the branch pipe with the main pipe at an angle of 90°.

- Tack-weld the joint with a 2 mm root gap to control distortion and to obtain penetration

- On Tee joint ,angle joints and cluster joints use a sequenceweldingtechnique.This prevents weld metal on

traction from pulling the pipe out of line. illustrate sone satisfactory sequence for aT-pipe assembly. When ever

possible, do all the welding in a down hand position. As in all pipe welding, the weld metal must be well fused

into the base metal. There must be good penetration and nounder cutting

- Manipulation of the torch during welding the’Tee’ joint should be correctly followed.

- Weld and complete the joint-clean

Note: Wear protective clothing.

• Tack-weld on both ends.

• Set the lap joint in a flat position.

• Deposit root run by using a 3.15mm dia. Medium coated M.S. electrode with 100-110 amps current.

Note: Ensure an electrode angle of 45° with the fillet corner and 80° with the welding line.

• Remove the slag with a chipping hammer and clean with a wire brush.

• Use tongs to hold the job.

• Wear chipping goggle for the protection of eyes.

• Deposit the final covering run with a weave motion using a 4.00 mm dia. Medium coated M.S. electrode

with150-160amps welding current.

Note: Prevent the upper edge of the plate from melting off.

• Remove the slag from the final weld and clean thoroughly.

Note: Use a weld gauge to check the fillet size.

• Inspect the lap fillet weld for surface defects and size.

233

CITS : C G & M - Welder - Exercise 60