Page 251 - CITS - Welder - Trade Practical

P. 251

WELDER - CITS

Skill Sequence

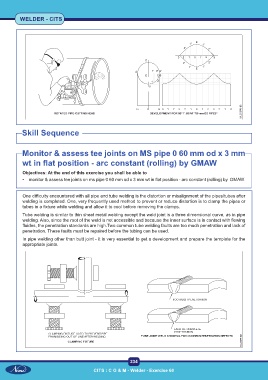

Monitor & assess tee joints on MS pipe 0 60 mm od x 3 mm

wt in flat position - arc constant (rolling) by GMAW

Objectives: At the end of this exercise you shall be able to

• monitor & assess tee joints on ms pipe 0 60 mm od x 3 mm wt in flat position - arc constant (rolling) by GMAW.

One difficulty encountered with all pipe and tube welding is the distortion or misalignment of the pipes/tubes after

welding is completed. One, very frequently used method to prevent or reduce distortion is to clamp the pipes or

tubes in a fixture while welding and allow it to cool before removing the clamps.

Tube welding is similar to thin sheet metal welding except the weld joint is a three dimensional curve, as in pipe

welding. Also, since the root of the weld is not accessible and because the inner surface is in contact with flowing

fluides, the penetration standards are high.Two common tube welding faults are too much penetration and lack of

penetration. These faults must be repaired before the tubing can be used.

In pipe welding other than butt joint - it is very essential to get a development and prepare the template for the

appropriate joints.

234

CITS : C G & M - Welder - Exercise 60