Page 256 - CITS - Welder - Trade Practical

P. 256

WELDER - CITS

• Deposit the final covering run with a weave motion using a 4.00 mm dia. Medium coated M.S. electrode

with150 160amps welding current.

Note : Prevent the upper edge of the plate from melting off.

• Remove the slag from the final weld and clean thoroughly.

Note : Use a weld gauge to check the fillet size.

• Inspect the lap fillet weld for surface defects and size.

Skill Sequence

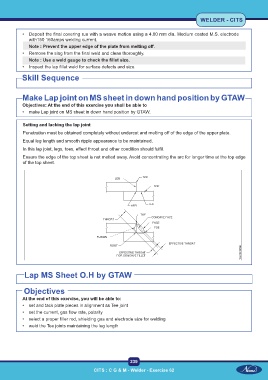

Make Lap joint on MS sheet in down hand position by GTAW

Objectives: At the end of this exercise you shall be able to

• make Lap joint on MS sheet in down hand position by GTAW.

Setting and lacking the lap joint

Penetration must be obtained completely without undercut and melting off of the edge of the upper plate.

Equal leg length and smooth ripple appearance to be maintained.

In this lap joint, legs, toes, effect throat and other condition should fulfil.

Ensure the edge of the top sheet is not melted away. Avoid concentrating the arc for longer time at the top edge

of the top sheet.

Lap MS Sheet O.H by GTAW

Objectives

At the end of this exercise, you will be able to:

• set and tack plate pieces in alignment as Tee joint

• set the current, gas flow rate, polarity

• select a proper filler rod, shielding gas and electrode size for welding

• weld the Tee joints maintaining the leg length

239

CITS : C G & M - Welder - Exercise 62