Page 259 - CITS - Welder - Trade Practical

P. 259

WELDER - CITS

Job Sequence

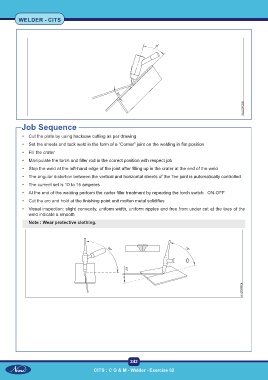

• Cut the plate by using hacksaw cutting as per drawing

• Set the sheets and tack weld in the form of a “Corner” joint on the welding in flat position

• Fill the crater

• Manipulate the torch and filler rod in the correct position with respect job

• Stop the weld at the left-hand edge of the joint after filling up in the crater at the end of the weld

• The angular distortion between the vertical and horizontal sheets of the Tee joint is automatically controlled

• The current set is 10 to 15 amperes

• At the end of the welding perform the carter filler treatment by repeating the torch switch ON-OFF

• Cut the arc and hold at the finishing point unit molten metal solidifies

• Visual inspection: slight convexity, uniform width, uniform ripples and free from under cut at the toes of the

weld indicate a smooth

Note : Wear protective clothing.

242

CITS : C G & M - Welder - Exercise 62