Page 45 - CITS - Welder - Trade Practical

P. 45

WELDER - CITS

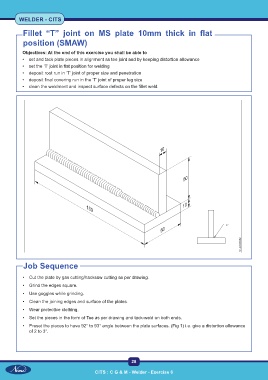

Fillet “T” joint on MS plate 10mm thick in flat

position (SMAW)

Objectives: At the end of this exercise you shall be able to

• set and tack plate pieces in alignment as tee joint and by keeping distortion allowance

• set the ‘T’ joint in flat position for welding

• deposit root run in ‘T’ joint of proper size and penetration

• deposit final covering run in the ‘T’ joint of proper leg size

• clean the weldment and inspect surface defects on the fillet weld.

Job Sequence

• Cut the plate by gas cutting/hacksaw cutting as per drawing.

• Grind the edges square.

• Use goggles while grinding.

• Clean the joining edges and surface of the plates.

• Wear protective clothing.

• Set the pieces in the form of Tee as per drawing and tack-weld on both ends.

• Preset the pieces to have 92° to 93° angle between the plate surfaces. (Fig 1) i.e. give a distortion allowance

of 2 to 3°.

28

CITS : C G & M - Welder - Exercise 6