Page 46 - CITS - Welder - Trade Practical

P. 46

WELDER - CITS

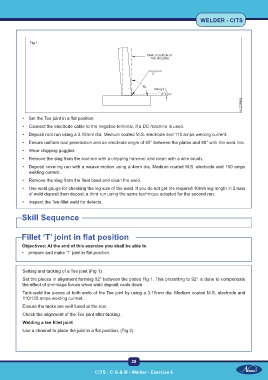

Fig 1

• Set the Tee joint in a flat position.

• Connect the electrode cable to the negative terminal, if a DC machine is used.

• Deposit root run using a 3.15mm dia. Medium coated M.S. electrode and 110 amps welding current.

• Ensure uniform root penetration and an electrode angle of 45° between the plates and 80° with the weld line.

• Wear chipping goggles.

• Remove the slag from the root run with a chipping hammer and clean with a wire brush.

• Deposit covering run with a weave motion using a 4mm dia. Medium coated M.S. electrode and 160 amps

welding current.

• Remove the slag from the final bead and clean the weld.

• Use weld gauge for checking the leg size of the weld. If you do not get the required 10mm leg length in 2 runs

of weld deposit then deposit a third run using the same technique adopted for the second run.

• Inspect the Tee fillet weld for defects.

Skill Sequence

Fillet ‘T’ joint in flat position

Objectives: At the end of this exercise you shall be able to

• prepare and make ‘T’ joint in flat position.

Setting and tacking of a Tee joint (Fig 1)

Set the pieces in alignment forming 92° between the plates Fig 1. This presetting to 92° is done to compensate

the effect of shrinkage forces when weld deposit cools down.

Tack-weld the pieces at both ends of the Tee joint by using a 3.15mm dia. Medium coated M.S. electrode and

110/120 amps welding current.

Ensure the tacks are well fused at the root.

Check the alignment of the Tee joint after tacking.

Welding a tee fillet joint

Use a channel to place the joint in a flat position. (Fig 2)

29

CITS : C G & M - Welder - Exercise 6