Page 50 - CITS - Welder - Trade Practical

P. 50

WELDER - CITS

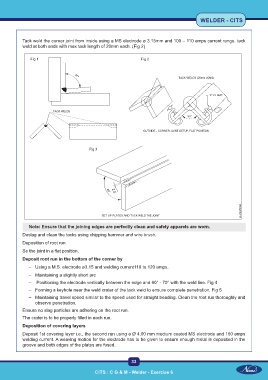

Tack weld the corner joint from inside using a MS electrode ø 3.15mm and 100 – 110 amps current range. tack

weld at both ends with max tack length of 20mm each. (Fig 2)

Fig 1 Fig 2

Fig 3

Note: Ensure that the joining edges are perfectly clean and safety apparels are worn.

Deslag and clean the tacks using chipping hammer and wire brush.

Deposition of root run

Se the joint in a flat position.

Deposit root run in the bottom of the corner by

– Using a M.S. electrode ø3.15 and welding current110 to 120 amps.

– Maintaining a slightly short arc

– Positioning the electrode vertically between the edge and 60° - 70° with the weld line. Fig 4

– Forming a keyhole near the weld crater of the tack weld to ensure complete penetration. Fig 5

– Maintaining travel speed similar to the speed used for straight beading. Clean the root run thoroughly and

observe penetration.

Ensure no slag particles are adhering on the root run.

The crater is to be properly filled in each run.

Deposition of covering layers

Deposit 1st covering layer i.e., the second run using a Ø 4.00 mm medium coated MS electrode and 160 amps

welding current. A weaving motion for the electrode has to be given to ensure enough metal is deposited in the

groove and both edges of the plates are fused.

33

CITS : C G & M - Welder - Exercise 6