Page 54 - CITS - Welder - Trade Practical

P. 54

WELDER - CITS

Job Sequence

• Straight cut two 10mm thick plates by gas cutting as per drawing and grind them to size.

• Bevel the edges of each plate to 30° angle by gas cutting and file the root face as per drawing.

• Clean the plates from dirt, water, oil, grease, paint etc.

• Keep the plates inverted in the form of a butt joint with proper root gap.

• Maintain a distortion allowance of 1.5° on each side of the joint.

• Wear all protective clothing.

• Use a 3.15mm medium coated MS electrode and set 110 amperes current. In case of DC welding machine

connect the electrode cable to the negative terminal of the machine.

• Tack weld on the back side of the plates at the ends. the length of tack should be 20mm.

• Deslag the tack weld and clean.

• Position the tack welded job on the table in flat position (the single V portion facing up)

• Deposit the root run and fill the crater as done for welding square butt joint. (Ex.No.3.06)

• Take special care to maintain key hole to ensure proper melting of root face and root penetration.

• Deposit the second run/intermittent run using 4mm ø medium coated electrode and 150-160 ampere current,

short arc and proper weaving of the electrode. Avoid excessive weaving and ensure normal travel speed.

• Fill the crater wherever necessary.

• Deslag.

• Deposit the third run/covering run using the same parameter and technique used for 2nd run. Ensure a proper

reinforcement of 1 to 1.5mm and avoid undercut.

• Inspect for any surface weld defect.

Skill Sequence

Welding of single ‘V’ butt joint MS plate 10mm thickness

in flat position

Objectives: At the end of this exercise you shall be able to

• weld single V butt joint MS plate 10mm in flat position.

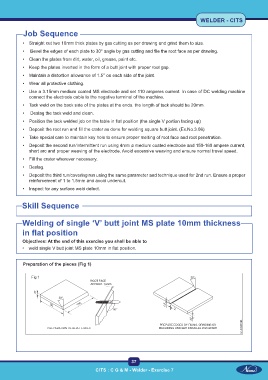

Preparation of the pieces (Fig 1)

Fig 1

37

CITS : C G & M - Welder - Exercise 7