Page 171 - CITS - Welder - Trade Theory

P. 171

WELDER - CITS

T - Tubular wire used in FCAW.

2 - Chemical composition of the wire.

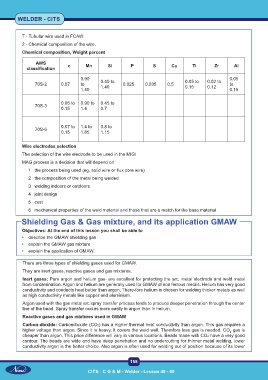

Chemical composition, Weight percent

AWS

classification c Mn Si P S Cu Ti Zr Al

0.90 0.05

70S-2 0.07 to 0.40 to 0.025 0.035 0.5 0.05 to 0.02 to to

0.12

0.15

1.40

1.40 0.15

0.06 to 0.90 to 0.45 to

70S-3

0.15 1.4 0.7

0.07 to 1.4 to 0.8 to

70S-6

0.15 1.85 1.15

Wire electrodes selection

The selection of the wire electrode to be used in the MIG/

MAG process is a decision that will depend on

1 the process being used (eg, solid wire or flux core wire)

2 the composition of the metal being welded

3 welding indoors or outdoors

4 joint design

5 cost

6 mechanical properties of the weld material and those that are a match for the base material.

Shielding Gas & Gas mixture, and its application GMAW

Objectives: At the end of this lesson you shall be able to

• describe the GMAW shielding gas

• explain the GMAW gas mixture

• explain the application of GMAW.

There are three types of shielding gases used for GMAW.

They are inert gases, reactive gases and gas mixtures.

Inert gases: Pure argon and helium gas- are excellent for protecting the arc, metal electrode and weld metal

from contamination. Argon and helium are generally used for GMAW of non ferrous metals. Helium has very good

conductivity and conducts heat better than argon. There-fore helium is chosen for welding thicker metals as well

as high conductivity metals like copper and aluminium.

Argon used with the gas metal arc spray transfer process tends to produce deeper penetration through the center

line of the bead. Spray transfer occurs more easily in argon than in helium.

Reactive gases and gas mixtures used in GMAW

Carbon-dioxide: Carbondioxide (CO2) has a higher thermal heat conductivity than argon. This gas requires a

higher voltage than argon. Since it is heavy, it covers the weld well. Therefore less gas is needed. CO gas is

2

cheaper than argon. This price difference will vary in various locations. Beads made with CO2 have a very good

contour. The beads are wide and have deep penetration and no undercutting for thinner metal welding, lower

conductivity argon is the better choice. Also argon is often used for welding out of position because of its lower

158

CITS : C G & M - Welder - Lesson 49 - 60 CITS : C G & M - Welder - Lesson 49 - 60