Page 168 - CITS - Welder - Trade Theory

P. 168

WELDER - CITS

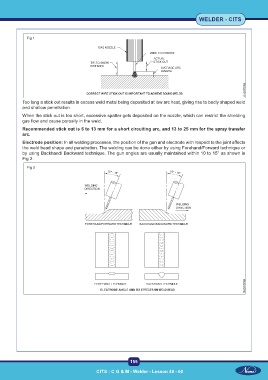

Fig 1

Too long a stick out results in excess weld metal being deposited at low arc heat, giving rise to badly shaped weld

and shallow penetration.

When the stick out is too short, excessive spatter gets deposited on the nozzle, which can restrict the shielding

gas flow and cause porosity in the weld.

Recommended stick out is 6 to 13 mm for a short circuiting arc, and 13 to 25 mm for the spray transfer

arc.

Electrode position: In all welding processes, the position of the gun and electrode with respect to the joint affects

the weld bead shape and penetration. The welding can be done either by using Forehand/Forward technique or

by using Backhand/ Backward technique. The gun angles are usually maintained within 10 to 15° as shown in

Fig 2.

Fig 2

155

CITS : C G & M - Welder - Lesson 49 - 60