Page 172 - CITS - Welder - Trade Theory

P. 172

WELDER - CITS

thermal conductivity. Argon gas is 10 times heavier than helium gas, hence less argon gas is required to provide

a good shield as compared to helium gas.

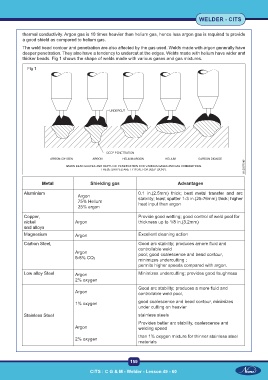

The weld bead contour and penetration are also affected by the gas used. Welds made with argon generally have

deeper penetration. They also have a tendency to undercut at the edges. Welds made with helium have wider and

thicker beads. Fig 1 shows the shape of welds made with various gases and gas mixtures.

Fig 1

Metal Shielding gas Advantages

Aluminium 0.1 in.(2.5mm) thick; best metal transfer and arc

Argon stability; least spatter 1-3 in.(25-76mm) thick; higher

75% Helium heat input than argon

25% argon

Copper, Provide good wetting; good control of weld pool for

nickel Argon thickness up to 1/8 in.(3.2mm)

and alloys

Magnesium Argon Excellent cleaning action

Carbon Steel, Good arc stability; produces amore fluid and

controllable weld

Argon pool; good coalescence and bead contour,

5-8% CO2 minimizes undercutting ;

permits higher speeds compared with argon.

Low alloy Steel Argon Minimizes undercutting; provides good toughness

2% oxygen

Good arc stability; produces a more fluid and

Argon controllable weld pool,

1% oxygen good coalescence and bead contour, minimizes

under cutting on heavier

Stainless Steel stainless steels

Provides better arc stability, coalescence and

Argon welding speed

than 1% oxygen mixture for thinner stainless steel

2% oxygen

materials

159

CITS : C G & M - Welder - Lesson 49 - 60