Page 174 - CITS - Welder - Trade Theory

P. 174

WELDER - CITS

Fig 2

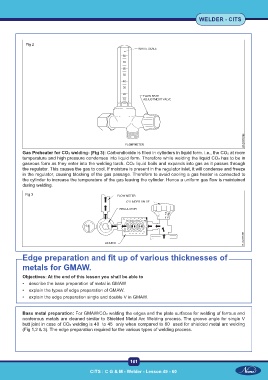

Gas Preheater for CO2 welding- (Fig 3): Carbondioxide is filled in cylinders in liquid form. i.e., the CO2 at room

temperature and high pressure condenses into liquid form. Therefore while welding the liquid CO2 has to be in

gaseous form as they enter into the welding torch. CO2 liquid boils and expands into gas as it passes through

the regulator. This causes the gas to cool. If moisture is present in the regulator inlet, it will condense and freeze

in the regulator, causing blocking of the gas passage. Therefore to avoid cooling a gas heater is connected to

the cylinder to increase the temperature of the gas leaving the cylinder. Hence a uniform gas flow is maintained

during welding.

Fig 3

Edge preparation and fit up of various thicknesses of

metals for GMAW.

Objectives: At the end of this lesson you shall be able to

• describe the base preparation of metal in GMAW

• explain the types of edge preparation of GMAW.

• explain the edge preparation single and double V in GMAW.

Base metal preparation: For GMAW/CO2 welding the edges and the plate surfaces for welding of ferrous and

nonferrous metals are cleaned similar to Shielded Metal Arc Welding process. The groove angle for single V

butt joint in case of CO2 welding is 40 to 45 only when compared to 60 used for shielded metal arc welding

(Fig 1,2 & 3). The edge preparation required for the various types of welding process.

161

CITS : C G & M - Welder - Lesson 49 - 60 CITS : C G & M - Welder - Lesson 49 - 60