Page 179 - CITS - Welder - Trade Theory

P. 179

WELDER - CITS

Causes Remedy

Material too thick. Joint preparation and design must

Improper joint preparation.

provide access to

bottom of groove while maintaining proper welding

Improper weld technique

wire extension and arc

Insufficient heat input. characteristics.

Maintain normal gun angle of 0 to 15 degrees to

achieve maximum penetration.

Keep arc on leading edge of weld puddle.

Be sure welding wire extends not more than (13 mm)

beyond nozzle.

Select higher wire feed speed and/or select higher

voltage range.

Reduce travel speed.

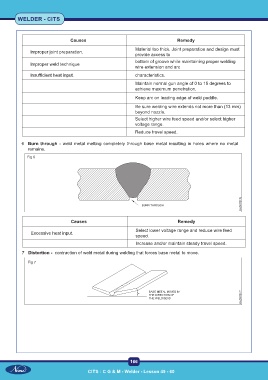

6 Burn through - weld metal melting completely through base metal resulting in holes where no metal

remains.

Fig 6

Causes Remedy

Select lower voltage range and reduce wire feed

Excessive heat input.

speed.

Increase and/or maintain steady travel speed.

7 Distortion - contraction of weld metal during welding that forces base metal to move.

Fig 7

166

CITS : C G & M - Welder - Lesson 49 - 60