Page 180 - CITS - Welder - Trade Theory

P. 180

WELDER - CITS

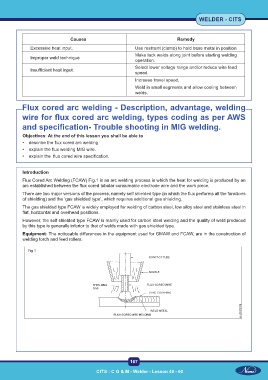

Causes Remedy

Excessive heat input. Use restraint (clamp) to hold base metal in position

Make tack welds along joint before starting welding

Improper weld technique

operation.

Select lower voltage range and/or reduce wire feed

Insufficient heat input.

speed.

Increase travel speed.

Weld in small segments and allow cooling between

welds.

Flux cored arc welding - Description, advantage, welding

wire for flux cored arc welding, types coding as per AWS

and specification- Trouble shooting in MIG welding.

Objectives: At the end of this lesson you shall be able to

• describe the flux cored arc welding

• explain the flux welding MIG wire.

• explain the flux cored wire specification.

Introduction

Flux Cored Arc Welding (FCAW) Fig.1 is an arc welding process in which the heat for welding is produced by an

arc established between the flux cored tubular consumable electrode wire and the work piece.

There are two major versions of the process, namely self shielded type (in which the flux performs all the functions

of shielding) and the ‘gas shielded type’, which requires additional gas shielding.

The gas shielded type FCAW is widely employed for welding of carbon steel, low alloy steel and stainless steel in

flat, horizontal and overhead positions.

However, the self shielded type FCAW is mainly used for carbon steel welding and the quality of weld produced

by this type is generally inferior to that of welds made with gas shielded type.

Equipment: The noticeable differences in the equipment used for GMAW and FCAW, are in the construction of

welding torch and feed rollers.

Fig 1

167

CITS : C G & M - Welder - Lesson 49 - 60