Page 190 - CITS - Welder - Trade Theory

P. 190

WELDER - CITS

Edge preparation and fit up for TIG welding sheet, plates,

and pipes

Objectives: At the end of this lesson you shall be able to

• describe the TIG welding low alloy steel

• explain the TIG welding aluminium sheets and pipe.

GTAW/TIG welding is generally recommended for pipe to pipe or tube to tube joints. TIG welding with inert gas

shielding produces the joints without any defect like gas porosity, oxide slag inclusions and hence the joints are

of superior quality. For MS/Carbon steel pipes and tubes, when welding is done with TIG process, the weld metal

is free from hydrogen entrapment which usually occurs in normal oxy acetylene gas welding or manual metal

arc welding processes. The hydrogen gas dissolved in the weld causes embrittlement during service. Hence

TIG welding for MS pipes is always preferred for all pipe lines viz., gas pipe lines/liquid lines in all petroleum and

power plant to convey high temperature and high pressure fluids (liquids & gases, steam etc.).

There are various pipe jointing’s like straight butt welds, fillet tee joints and pipe elbow joints to suit the piping

layout of any process plant say petroleum or power generating plant.

Therefore it is mandatory to take utmost care in development of members of pipe joints so that the geometry will

provide appropriate clearances for the joint fit up and the TIG welds so produced will be free from any defect and

will offer highest joint efficiency as per the design standards.

Various configuration of the joints is well shown in practical Exercise book.

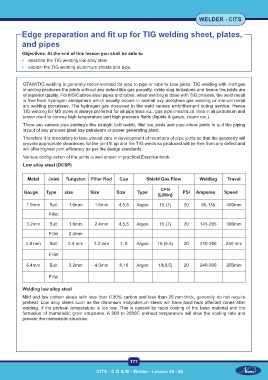

Low alloy steel (DCSP)

Metal Joint Tungsten Filler Rod Cup Shield Gas Flow Welding Travel

CFH

Gauge Type size Size Size Type PSI Amperes Speed

(L/Min}

1.6mm Butt 1.6mm 1.6mm 4,5,6 Argon 15 (7) 20 95-135 400mm

Fillet

3.2mm Butt 1.6mm 2.4mm 4,5,6 Argon 15 (7) 20 145-205 300mm

Fillet 2.4mm

4.8 mm Butt 2.4 mm 3.2 mm 7, 8 Argon 16 (6.5) 20 210-260 250 mm

Fillet

6.4mm Butt 3.2mm 4.0mm 8,10 Argon 18(8,5) 20 240-300 250mm

Fillet

Welding low alloy steel

Mild and low carbon steels with less than 0.30% carbon and less than 25 mm thick, generally do not require

preheat. Low alloy steels such as the chromium molybdenum steels will have hard heat affected zones after

welding, if the preheat temperature is too low. This is caused by rapid cooling of the base material and the

formation of martensitic grain structures. A 900 to 2000C preheat temperature will slow the cooling rate and

prevent the martensitic structure.

177

CITS : C G & M - Welder - Lesson 49 - 60