Page 194 - CITS - Welder - Trade Theory

P. 194

WELDER - CITS

3 Thoriated Tungsten Electrodes (Ew Ts-1 And Ew Th-2)

Thorium Oxide (Th O2), which is called throne is another oxide used to alloy tungsten electrodes Two types

of thoriated tungsten electrodes are readily available .The EW Th -1 electrodes contain a nominal Wt% thoria

and the EW Th 2 electrodes contain a normal

2 Wt-% thoria evenly disposed throughout their entire length . The 1 Wt% thorated tungsten electrodes have

a yellow colour, while the 2 W% thoriated tungsten electrodes have a red colour identification

4 Ceriated Tungsten Electrodes (Ew Co-2)

The EW Ce2, electrodes are tungsten alloy electrodes that contain a nominal 2 Wt-% Cerium Oxide (CeO2,

referred to as ceria) These electrodes have an orange colour code.

The ceriated tungsten electrodes were developed as possible replacements for thoriated tungsten electrodes,

because ceria, unlike thoria is not radio-active material. Compared with pure tungsten, the ceriated tungsten

electrodes provide similar current level, and the improved arc starting band arc stability characteristics of

thoriated tungsten electrodes. They also tent to have longer life than thoriated tungsten electrodes. EW Ce-2

ELECTRODES WILL OPERATE SUCCESSFULLY WITH AC OR DC

5 Lanthanated Tungsten Electrodes (Ew La-1)

The lanthanated (EW La-1) tungsten electrodes were developed around the same time as the ceriated

tungsten electrodes and for the same reason, that is Lanthana is not radio active These electrodes contain a

nominal 1 W% lanthanium oxide (La O ), referred to a Lanthana The current levels, advantages and operating

2

2

characteristics of these electrodes are very similar to the ceriated tungsten electrodes. THESE MAY HAVE

OPERATING CHARACTERISTICS SIMILAR TO THE EW C-2 AND EW Th-2

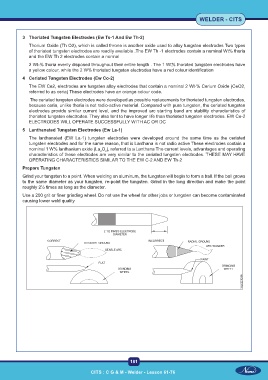

Prepare Tungsten

Grind your tungsten to a point. When welding on aluminum, the tungsten will begin to form a ball. If the ball grows

to the same diameter as your tungsten, re-point the tungsten. Grind in the long direction and make the point

roughly 2½ times as long as the diameter.

Use a 200 grit or finer grinding wheel. Do not use the wheel for other jobs or tungsten can become contaminated

causing lower weld quality

181

CITS : C G & M - Welder - Lesson 61-76