Page 199 - CITS - Welder - Trade Theory

P. 199

WELDER - CITS

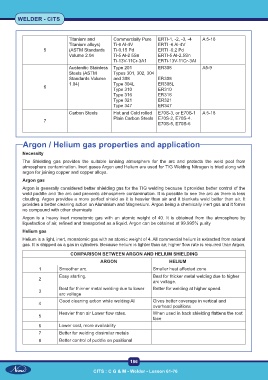

Titanium and Commercially Pure ERTI-1, -2, -3, -4 A 5-16

Titanium alloys) Ti-6 Al-4V ERTI -6 Al-4V

5 (ASTM Standards Ti-0.15 Pd ERTI -0.2 Pd

Volume 2.04 Ti-5 Al-2 5Sn ERTI-5 AI-2.5Sn

Ti-13V-11Cr-3A1 ERTi-13V-11Cr-3AI

Austenitic Stainless Type 201 ER308 A5-9

Steels (ASTM Types 301, 302, 304

Standards Volume and 308 ER308

1.04) Type 304L ER308L

6 Type 310 ER310

Type 316 ER316

Type 321 ER321

Type 347 ER347

Carbon Steels Hot and Cold rolled E70S-3, or E70S-1 A 5-18

Plain Carbon Steels E70S-2, E70S-4.

7

E70S-5, E70S-6

Argon / Helium gas properties and application

Necessity

The Shielding gas provides the suitable ionising atmosphere for the arc and protects the weld pool from

atmosphere contamination. Inert gases Argon and Helium are used for TIG Welding Nitrogen is tried along with

argon for joining copper and copper alloys.

Argon gas

Argon is generally considered better shielding gas for the TIG welding because it provides better control of the

weld puddle and the arc and prevents atmosphere contamination. It is possible to see the arc as there is less

clouding. Argon provides a more perfect shield as it is heavier than air and it blankets weld better than air. It

provides a better cleaning action on Aluminium and Magnesium. Argon being a chemically inert gas and it forms

no compound with other chemicals

Argon is a heavy inert monatomic gas with an atomic weight of 40. It is obtained from the atmosphere by

liquefaction of air, refined and transported as a liquid. Argon can be obtained at 99.995% purity

Helium gas

Helium is a light, inert, monatomic gas with an atomic weight of 4. All commercial helium is extracted from natural

gas. It is shipped as a gas in cylinders. Because helium is lighter than air, higher flow rate is required than Argon.

COMPARISON BETWEEN ARGON AND HELIUM SHIELDING

ARGON HELIUM

1 Smoother arc. Smaller heat affected zone

Easy starting. Best for thicker metal welding due to higher

2

arc voltage.

Best for thinner metal welding due to lower Better for welding at higher speed.

3

arc voltage

Good cleaning action while welding Al Gives better coverage in vertical and

4

overhead positions

Heavier than air Lower flow rates. When used in back shielding flattens the root

5

face

6 Lower cost, more availability

7 Better for welding dissimilar metals

8 Better control of puddle on positional

186

CITS : C G & M - Welder - Lesson 61-76 CITS : C G & M - Welder - Lesson 61-76