Page 196 - CITS - Welder - Trade Theory

P. 196

WELDER - CITS

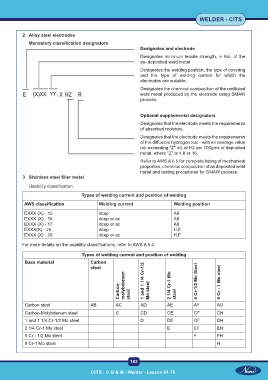

2 Alloy steel electrodes

Mandatory classification designators

Designates and electrode

Designates minimum tensile strength, in Ksi, of the

as- deposited weld metal

Designates the welding position, the type of covering

and the type of welding current for which the

electrodes are suitable.

Designates the chemical composition of the undiluted

weld metal produced by the electrode using SMAW

process.

Optional supplemental designators

Designates that the electrode meets the requirements

of absorbed moisture.

Designates that the electrode meets the requirements

of the diffusible hydrogen test - with an average value

not exceeding "Z" mL of H2 per 100gms of deposited

metal, where "Z" is 4,8 or 16.

Refer to AWS A 5.5 for complete listing of mechanical

properties, chemical composition of as deposited weld

metal and testing procedures for SMAW process.

3 Stainless steel filler metal

Usability classification

Types of welding current and position of welding

AWS classification Welding current Welding position

EXXX (X) - 15 dcep All

EXXX (X) - 16 dcep or ac All

EXXX (X) - 17 dcep or ac All

EXXX(X) - 25 dcep H,F

EXXX (X) - 26 dcep or ac H,F

For more details on the usability classifications, refer to AWS A 5.4

Types of welding current and position of welding

Base material Carbon

steel

Carbon- molybdenum steel 1 and 1 1/4 Cr-1/2 Mo steel 2 1/4 Cr-1 Mo steel 5 Cr-1/2 Mo Steel 9 Cr - 1 Mo steel

Carbon steel AB AC AD AE AF AG

Carbon-Molybdenum steel C CD CE CF CH

1 and 1 1/4 Cr-1/2 Mo steel D DE DF DH

2 1/4 Cr-1 Mo steel E EF EH

5 Cr - 1/2 Mo steel F FH

9 Cr-1 Mo steel H

183

CITS : C G & M - Welder - Lesson 61-76