Page 197 - CITS - Welder - Trade Theory

P. 197

WELDER - CITS

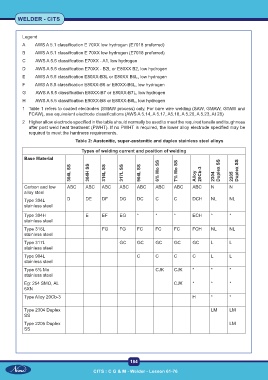

Legend

A AWS A 5.1 classification E 70XX low hydrogen (E7018 preferred)

B AWS A 5.1 classification E 70XX low hydrogen (E7018 preferred)

C AWS A 5.5 classification E70XX - A1, low hydrogen

D AWS A 5.5 classification E70XX - B2L or E80XX B2, low hydrogen

E AWS A 5.5 classification E80XX-B3L or E80XX B6L, low hydrogen

F AWS A 5.5 classification E80XX-B6 or E80XX-B6L, low hydrogen

G AWS A 5.5 classification E80XX-B7 or E80XX-B7L, low hydrogen

H AWS A 5.5 classification E90XX-B8 or E80XX-B8L, low hydrogen

1 Table 1 refers to coated electrodes (SMAW process) only. For bare wire welding (SAW, GMAW, GTAW and

FCAW), use equivalent electrode classifications (AWS A 5.14, A 5.17, A5.18, A 5.20, A 5.23, At 28)

2 Higher allow electrode specified in the table should normally be used to meet the required tensile and toughness

after post weld heat treatment (PWHT). If no PWHT is required, the lower alloy electrode specified may be

required to meet the hardness requirements.

Table 2: Austenitic, super-austenitic and duplex stainless steel alloys

Types of welding current and position of welding

Base Material

304L SS 304H SS 316L SS 317L SS 904L SS 6% Mo SS 7% Mo SS Alloy 20Cb-3 2304 Duplex SS 2205 Duplex SS

Carbon and low ABC ABC ABC ABC ABC ABC ABC ABC N N

alloy steel

Type 304L D DE DF DG DC C C DCH NL NL

stainless steel

Type 304H E EF EG * * * ECH * *

stainless steel

Type 316L FG FG FC FC FC FCH NL NL

stainless steel

Type 317L GC GC GC GC GC L L

stainless steel

Type 904L C C C C L L

stainless steel

Type 6% Mo CJK CJK * * *

stainless steel

Eg: 254 SMO, AL CJK * * *

6XN

Type Alloy 20Cb-3 H * *

Type 2304 Duplex LM LM

SS

Type 2205 Duplex LM

SS

184

CITS : C G & M - Welder - Lesson 61-76 CITS : C G & M - Welder - Lesson 61-76