Page 200 - CITS - Welder - Trade Theory

P. 200

WELDER - CITS

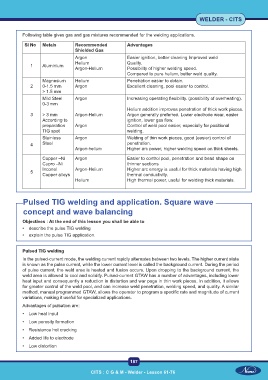

Following table gives gas and gas mixtures recommended for the welding applications.

Sl No Metals Recommended Advantages

Shielded Gas

Argon Easier ignition, better cleaning Improved weld

Helium Quality.

1 Aluminium

Argon-Helium Possibility of higher welding speed.

Compared to pure helium, better weld quality.

Magnesium Helium Penetration easier to obtain.

2 0-1.5 mm Argon Excellent cleaning, pool easier to control.

> 1.5 mm

Mild Steel Argon Increasing operating flexibility. (possibility of overheating).

0-3 mm

Helium addition improves penetration of thick work pieces.

3 > 3 mm Argon-Helium Argon generally preferred. Lower electrode wear, easier

According to ignition, lower gas flow.

preparation Argon Control of weld pool easier, especially for positional

TIG spot welding.

Stainless Argon Welding of thin work pieces, good (easier) control of

4 Steel penetration.

Argon-helium Higher arc power, higher welding speed on thick sheets.

Copper –Ni Argon Easier to control pool, penetration and bead shape on

Cupro –Ni thinner sections

Inconel Argon-Helium Higher arc energy is useful for thick materials having high

5

Copper alloys thermal conductivity.

Helium High thermal power, useful for welding thick materials.

Pulsed TIG welding and application. Square wave

concept and wave balancing

Objectives : At the end of this lesson you shall be able to

• describe the pulse TIG welding

• explain the pulse TIG application.

Pulsed TIG welding

In the pulsed-current mode, the welding current rapidly alternates between two levels. The higher current state

is known as the pulse current, while the lower current level is called the background current. During the period

of pulse current, the weld area is heated and fusion occurs. Upon dropping to the background current, the

weld area is allowed to cool and solidify. Pulsed-current GTAW has a number of advantages, including lower

heat input and consequently a reduction in distortion and war page in thin work pieces. In addition, it allows

for greater control of the weld pool, and can increase weld penetration, welding speed, and quality. A similar

method, manual programmed GTAW, allows the operator to program a specific rate and magnitude of current

variations, making it useful for specialized applications.

Advantages of pulsation are:

• Low heat input

• Low porosity formation

• Resistance hot cracking

• Added life to electrode

• Low distortion

187

CITS : C G & M - Welder - Lesson 61-76