Page 205 - CITS - Welder - Trade Theory

P. 205

WELDER - CITS

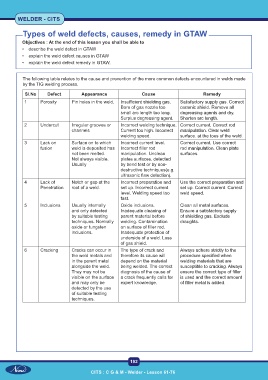

Types of weld defects, causes, remedy in GTAW

Objectives : At the end of this lesson you shall be able to

• describe the weld defect in GTAW

• explain the weld defect causes in GTAW

• explain the weld defect remedy in GTAW.

The following table relates to the cause and prevention of the more common defects encountered in welds made

by the TIG welding process.

Sl.No Defect Appearance Cause Remedy

1 Porosity Pin holes in the weld. Insufficient shielding gas. Satisfactory supply gas. Correct

Bore of gas nozzle too ceramic shield. Remove all

small arc length too long. degreasing agents and dry.

Surplus degreasing agent. Shorten arc length.

2 Undercut Irregular grooves or Incorrect welding technique. Correct current. Correct rod

channels Current too high. Incorrect manipulation. Clear weld

welding speed. surface. at the toes of the weld.

3 Lack on Surface on to which Incorrect current level. Correct current. Use correct

fusion weld is deposited has Incorrect filler rod rod manipulation. Clean plate

not been melted. manipulation. Unclean surfaces.

Not always visible. plates surfaces. detected

Usually by bend test or by non-

destructive techniques(e.g.

ultrasonic flaw detection).

4 Lack of Notch or gap at the Incorrect preparation and Use the correct preparation and

Penetration root of a weld. set up. Incorrect current set up. Correct current. Correct

level. Welding speed too weld speed.

fast.

5 Inclusions Usually internally Oxide inclusions. Clean all metal surfaces.

and only detected Inadequate cleaning of Ensure a satisfactory supply

by suitable testing parent material before of shielding gas. Exclude

techniques. Normally welding. Contamination draughts.

oxide or tungsten on surface of filler rod.

inclusions. Inadequate protection of

underside of a weld. Loss

of gas shield.

6 Cracking Cracks can occur in The type of crack and Always adhere strictly to the

the weld metals and therefore its cause will procedure specified when

in the parent metal depend on the material welding materials that are

alongside the weld. being welded. The correct susceptible to cracking. Always

They may not be diagnosis of the cause of ensure the correct type of filler

visible on the surface a crack frequently calls for is used and the correct amount

and may only be expert knowledge. of filler metal is added.

detected by the use

of suitable testing

techniques.

192

CITS : C G & M - Welder - Lesson 61-76