Page 214 - CITS - Welder - Trade Theory

P. 214

WELDER - CITS

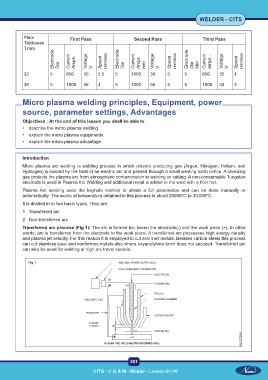

Plate First Pass Second Pass Third Pass

Thickness

T,mm

Electrode Dia Current Amps. Voltage Speed mm/sec Electrode Dia Current Amps mm Voltage Speed mm/sec Electrode Dia Mm Current amps . Voltage Speed mm/sec

32 5 850 35 V 5.5 5 1000 36 V 5 5 850 35 V 4

38 5 1000 36 4 5 1000 36 4 5 1000 34 3

Micro plasma welding principles, Equipment, power

source, parameter settings, Advantages

Objectives : At the end of this lesson you shall be able to

• describe the micro plasma welding

• explain the micro plasma equipments

• explain the micro plasma advantage.

Introduction

Micro plasma arc welding is welding process in which plasma producing gas (Argon, Nitrogen, Helium, and

Hydrogen) is ionized by the heat of an electric arc and passed through a small welding torch orifice. A shielding

gas protects the plasma arc from atmospheric contamination in welding or cutting. A non-consumable Tungsten

electrode is used in Plasma Arc Welding and additional metal is added to the weld with a filler rod.

Plasma Arc welding uses the keyhole method to obtain a full penetration and can be done manually or

automatically. The works of temperature obtained in this process is about 20000ºC to 30,000ºC.

It is divided in to two basic types. They are:

1 Transferred arc

2 Non-transferred arc

Transferred arc process (Fig 1): The arc is formed be- tween the electrode(-) and the work piece (+). In other

words, arc is transferred from the electrode to the work piece. A transferred arc possesses high energy density

and plasma jet velocity. For this reason it is employed to cut and melt metals. Besides carbon steels this process

can cut stainless steel and nonferrous metals also where oxyacetylene torch does not succeed. Transferred arc

can also be used for welding at high arc travel speeds.

Fig 1

201

CITS : C G & M - Welder - Lesson 61-76