Page 211 - CITS - Welder - Trade Theory

P. 211

WELDER - CITS

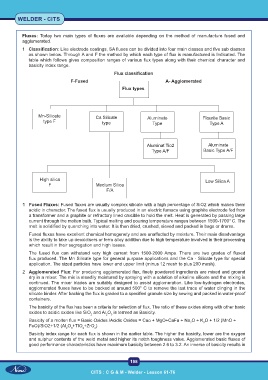

Fluxes: Today two main types of fluxes are available depending on the method of manufacture fused and

agglomerated.

1 Classification: Like electrode coatings, SA fluxes can be divided into four main classes and five sub classes

as shown below. Through A and F the method by which each type of flux is manufactured is Indicated. The

table which follows gives composition ranges of various flux types along with their chemical character and

basicity index range.

Flux classification

F-Fused A- Agglomerated

Flux types

Mn-Silicate Ca Silicate Aluminate Flourite Basic

type F type Type Type A

Aluminat Tio2 Aluminate

Type A/F Basic Type A/F

High silica Low Silica A

F Medium Silica

F/A

1 Fused Fluxes: Fused fluxes are usually complex silicate with a high percentage of SiO2 which makes them

acidic in character. The fused flux is usually produced in an electric furnace using graphite electrode fed from

a transformer and a graphite or refractory lined crucible to hold the melt. Heat is generated by passing large

current through the molten bath. Typical melting and pouring temperature ranges between 1500-1700° C. The

melt is solidified by quenching into water. It is then dried, crushed, sieved and packed in bags or drums.

Fused fluxes have excellent chemical homogenety and are unaffected by moisture. Their main disadvantage

is the ability to take up deoxidisers or ferro alloy addition due to high temperature involved in their processing

which result in their segregation and high losses.

The fused flux can withstand very high current from 1500-2000 Amps. There are two grades of fluxed

flux produced. The Mn Silicate type for general purpose applications and the Ca - Silicate type for special

application. The sized particles have lower and upper limit (minus 12 mesh to plus 200 mesh).

2 Agglomerated Flux: For producing agglomerated flux, finely powdered ingredients are mixed and ground

dry in a mixer. The mix is steadily moistured by spraying with a solution of alkaline silicate and the mixing is

continued. The mixer blades are suitably designed to assist agglomeration. Like low-hydrogen electrodes,

agglomerated fluxes have to be backed at around 500° C to remove the last trace of water clinging in the

silicate binder. After backing the flux is graded to a specified granule size by sewing and packed in water-proof

containers.

The basicity of the flux has been a criteria for selection of flux. The ratio of these oxides along with other basic

oxides to acidic oxides like SiO and Al O is termed as Basicity.

2 2 3

Basicity of a molten flux = Basic Oxides /Acidic Oxides = Cao + MgO+CaFa + Na O + K O + 1/2 (MnO +

2

2

FeO)/SiO2+1/2 (Al O +TIO +ZrO )

3

2

2

2

Basicity index range for each flux is shown in the earlier table. The higher the basicity, lower are the oxygen

and sulphur contents of the weld metal and higher its notch toughness value. Agglomerated basic fluxes of

good performance characteristics have maximum basicity between 2.6 to 3.2. An inverse of basicity results in

198

CITS : C G & M - Welder - Lesson 61-76