Page 216 - CITS - Welder - Trade Theory

P. 216

WELDER - CITS

Micro plasma and medium current plasma advantages

• energy concentration is greater & higher welding speed

• energy concentration is greater & lower current is needed to produce a given weld & less distortions

• improved arc stability

• arc column has greater directional stability

• narrow bead & less distortions • less need for fixturing

• variations in torch stand-off distance have little effect on bead width or heat concentration & positional weld

is much easy

• tungsten electrode is recessed & no tungsten contamination, less time for repointing, greater tolerance to

surface contamination (including coatings).

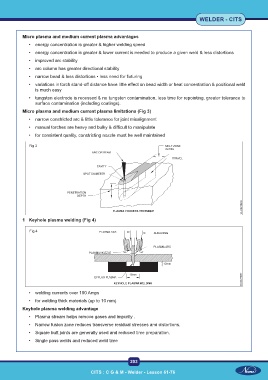

Micro plasma and medium current plasma limitations (Fig 3)

• narrow constricted arc & little tolerance for joint misalignment

• manual torches are heavy and bulky & difficult to manipulate

• for consistent quality, constricting nozzle must be well maintained

Fig 3

1 Keyhole plasma welding (Fig 4)

Fig 4

• welding currents over 100 Amps

• for welding thick materials (up to 10 mm)

Keyhole plasma welding advantage

• Plasma stream helps remove gases and impurity .

• Narrow fusion zone reduces transverse residual stresses and distortions.

• Square butt joints are generally used and reduced time preparation.

• Single pass welds and reduced weld time

203

CITS : C G & M - Welder - Lesson 61-76