Page 147 - CITS - Dress Making - TT - 2024

P. 147

DRESS MAKING - CITS

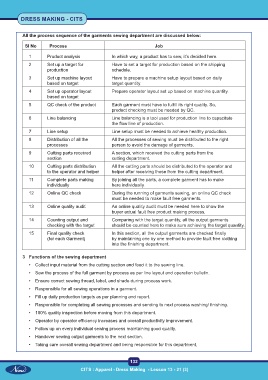

All the process sequence of the garments sewing department are discussed below:

Sl No Process Job

1 Product analysis In which way, a product has to sew, it’s decided here.

2 Set up a target for Have to set a target for production based on the shipping

production schedule.

3 Set up machine layout Have to prepare a machine setup layout based on daily

based on target target quantity.

4 Set up operator layout Prepare operator layout set up based on machine quantity.

based on target

5 QC check of the product Each garment must have to fulfill its right quality. So,

product checking must be needed by QC.

6 Line balancing Line balancing is a tool used for production line to capacitate

the flow line of production.

7 Line setup Line setup must be needed to achieve healthy production.

8 Distribution of all the All the processes of sewing must be distributed to the right

processes person to avoid the damage of garments.

9 Cutting parts received A section, which received the cutting parts from the

section cutting department.

10 Cutting parts distribution All the cutting parts should be distributed to the operator and

to the operator and helper helper after receiving those from the cutting department.

11 Complete parts making By joining all the parts, a complete garment has to make

individually here individually.

12 Online QC check During the running of garments sewing, an online QC check

must be needed to make fault free garments.

13 Online quality audit An online quality audit must be needed here to show the

buyer actual fault free product making process.

14 Counting output and Comparing with the target quantity, all the output garments

checking with the target should be counted here to make sure achieving the target quantity.

15 Final quality check In this section, all the output garments are checked finally

(for each Garment) by maintaining one by one method to provide fault free clothing

into the finishing department.

3 Functions of the sewing department

• Collect input material from the cutting section and feed it to the sewing line.

• Sew the process of the full garment by process as per line layout and operation bulletin.

• Ensure correct sewing thread, label, and shade during process work.

• Responsible for all sewing operations in a garment.

• Fill up daily production targets as per planning and report.

• Responsible for completing all sewing processes and sending to next process washing/ finishing.

• 100% quality inspection before moving from this department.

• Operator by operator efficiency increases and overall productivity improvement.

• Follow up on every individual sewing process maintaining good quality.

• Handover sewing output garments to the next section.

• Taking care overall sewing department and being responsible for this department.

132

CITS : Apparel - Dress Making - Lesson 13 - 21 (3)